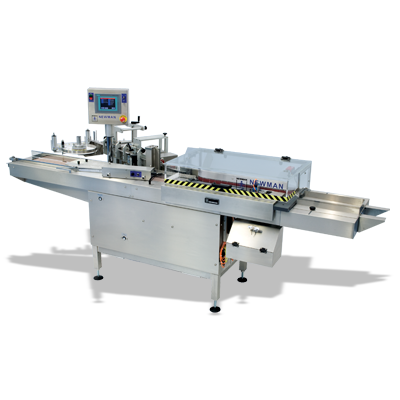

Discover Our 6VAL Labelling Machine

A labelling system designed to apply both clear and paper self-adhesive labels to a range of rigid cylindrical containers.

About 6VAL Labelling Machine

Typically, the containers to be labelled are supplied in trays which can be manually loaded at the infeed of the machine with labelled products being automatically reloaded onto empty trays at the outfeed.

Each individual container is detected at the labelling point as it passes beneath a sensor, at which point the label feed is activated. The leading edge of the label is driven off the backing web at a linear speed which matches the container speed; this ensures smooth, accurate placement on the container surface.

The container, gripped between an applicator belt and presser pad, is controlled as the entire label is pressed firmly in place, ensuring high registration accuracy.

Machine Features

-

High GMP design

-

Stainless steel construction

-

Inline or tray loading/unloading

-

PLC control

-

Colour touch screen HMI interface panel

-

Full counter-package

-

Full ‘positive accept’ security system

-

Newman straight labelling arm

-

Automatic critical device checking

-

Single AC motor drive gives synchronised infinitely variable speed control

-

In Process Control

Machine Options

-

Production data printout

-

Bar code reading systems

-

Hot foil, thermal transfer, laser printing options

-

Easisplice 470 module enables reel changes without labelling downtime

-

Vision Systems, for OCV/OCR/barcode

-

Ultrasonic label sensors for paper and clear labels

-

Full validation documentation package

Standard Specification

|

Name

|

Age

|

|---|---|

|

Container Diameter

|

10mm-50mm

|

|

Labels Min

|

12mm (H) x 100mm (L)

|

|

Labels Max

|

25mm (H) x 160mm (L)

|

|

Min. Height to Bottom of Label

|

1mm

|

|

Max. Label Reel Diameter

|

300mm

|

|

Min Core Diameter

|

45mm

|

|

Tray Size

|

400 x 180mm

|

|

Net Weight

|

475 Kg

|

|

Electrical Supply

|

230V-1Ph-50Hz, 1KW (60Hz option)

|

|

Compressed Air

|

60psi/4.2 Bar

|

|

Noise Emission:

|

<75dB @ 1m (subject to container type)

|

Labelling Products of 6VAL

The 6VAL labelling system is designed to apply both clear and paper self-adhesive labels to a range of rigid cylindrical containers.

Ampoules

Discover Our Ampoules Labelling Solutions.

Vials

Discover Our Vials Labelling Solutions.

Driven by Exceptional Service and Support

FDA Approved

The company also provides a full validation service to FDA, European and other national and international standards enabling easy progress through the necessary qualification procedures.

Secret to Success

Our success stems from a blend of high-quality service, precise and reliable equipment, efficient and thorough validation, skilled engineers, and the extensive experience of our staff.

High Quality Machinery

The products manufactured by Newman Labelling Limited are designed and built to meet and surpass the rigorous Quality requirements of the Pharmaceutical Industry.

Since

0

Pharma Labelling Machines

0

+

Countries Covered

0

+ Years

MAchine Still Running

0

CPM +

Machine Speed

Frequently Asked Questions

Explore these frequently asked questions to gain a deeper understanding of Newman Labelling Machines.

Newman’s labelling machines can accommodate a wide range of pharmaceutical products, including ampoules, vials, syringes, glass and plastic bottles, cartons, and carpoules.

Faulty Label Removal System is an automatic Faulty Label Removal (FLR) System designed to reduce your waste by removing ‘faulty’ labels from the labelling process prior to application.

The three main highlights of Faulty Label Removal are:

- Faulty labels are removed before application to the product.

- Faulty labels are rejected individually.

- Unlabelled products are rejected.

It’s essential to consider certain factors, such as readability, durability, tamper-proofing, and many more when it comes to labelling pharmaceutical products.

In the UK, the labelling of pharmaceutical products is subject to strict regulation by the Medicines and Healthcare Products Regulatory Agency (MHRA). The labelling of medications must include comprehensive information such as:

- Name and strength of medicine

- Dosage of strength

- Expiry date

- Warning and Precautions

- Route of administration

Pharmaceutical companies are required to follow strict regulations concerning different aspects of their products, including but not limited to how they are identified, dosage information, expiration dates, storage conditions, and safety warnings.

Pharmaceutical companies face major obstacles when it comes to labelling pharmaceutical products due to the value of what’s inside the container, limited labelling areas, and strict regulatory requirements. The readability and accuracy of information are crucial but can be difficult to achieve given the delicate nature of the pharmaceutical containers. Keeping up with standards is also critical, making the labelling process even more challenging.

Newman’s Labelling machines have different levels of automation, including reject station and verification, barcode, automatic loading/unloading station, and many more.

OUR CLIENTS