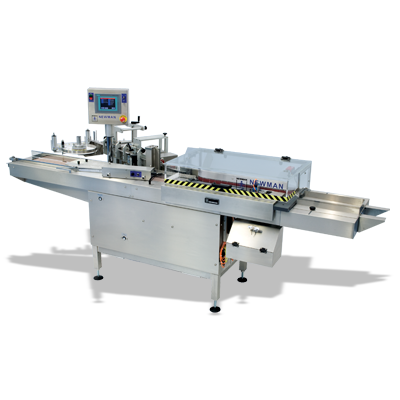

Discover Our CTE350 Labelling Machine

A fully automatic labelling system which applies self-adhesive tamper-evident and hologram labels (security labels) to erected cartons.

About CTE350 Labelling Machine

At the infeed, cartons are separated, held under a top belt and transported past two stepper motor-driven label stations. Labels are dispensed on to the overhanging vertical faces of the carton and applied with a roller.

Aeroplane and reverse tuck formats can be accommodated. Cartons proceed to the sensing station where sensors detect label presence prior to wipe down.

Both labels must be present for a carton to be accepted; if not, it is ejected into a secure reject area.

Machine Features

-

Compact

-

GMP Design

-

Stainless steel finish

-

In Process Control

-

Stepper motor drive for label web

-

“Positive accept” security system

-

Automatic critical device checking

-

Reject verification

-

Product and reject counter package

-

All adjustments scaled for repeatability

-

No change parts

-

Validation Documentation Package

Machine Options

-

Easisplice 470 module enables reel changes without labelling downtime (2 required)

Standard Specification

|

Name

|

Age

|

|---|---|

|

Carton size

|

Min 12mm(H) x 20mm(W) x 65mm(L) Max 120mm(H) x 120mm(W) x 240mm(L)

|

|

Labels Min

|

10mm (H) x 10mm (L)

|

|

Labels Max

|

40mm (H) x 25mm (L)

|

|

Max. Label Reel Diameter

|

300mm

|

|

Speed

|

Variable up to 350 CPM

|

|

Net Weight

|

420 Kg

|

|

Electrical Supply

|

230V-1Ph-50Hz, 1KW (60Hz option)

|

|

Compressed Air

|

60psi/4.2 Bar

|

|

Noise Emission:

|

<75dB @ 1m (subject to container type)

|

Labelling Products of CTE350

The CTE350 is a fully automatic labelling system which applies self-adhesive tamper-evident and hologram labels (security labels) to erected cartons.

Cartons

Discover Our Carton Labelling Solutions.

Driven by Exceptional Service and Support

FDA Approved

The company also provides a full validation service to FDA, European and other national and international standards enabling easy progress through the necessary qualification procedures.

Secret to Success

Our success stems from a blend of high-quality service, precise and reliable equipment, efficient and thorough validation, skilled engineers, and the extensive experience of our staff.

High Quality Machinery

The products manufactured by Newman Labelling Limited are designed and built to meet and surpass the rigorous Quality requirements of the Pharmaceutical Industry.

Since

0

Pharma Labelling Machines

0

+

Countries Covered

0

+ Years

MAchine Still Running

0

CPM +

Machine Speed

Frequently Asked Questions

Explore these frequently asked questions to gain a deeper understanding of Newman Labelling Machines.

Newman’s labelling machines can accommodate a wide range of pharmaceutical products, including ampoules, vials, syringes, glass and plastic bottles, cartons, and carpoules.

Faulty Label Removal System is an automatic Faulty Label Removal (FLR) System designed to reduce your waste by removing ‘faulty’ labels from the labelling process prior to application.

The three main highlights of Faulty Label Removal are:

- Faulty labels are removed before application to the product.

- Faulty labels are rejected individually.

- Unlabelled products are rejected.

It’s essential to consider certain factors, such as readability, durability, tamper-proofing, and many more when it comes to labelling pharmaceutical products.

In the UK, the labelling of pharmaceutical products is subject to strict regulation by the Medicines and Healthcare Products Regulatory Agency (MHRA). The labelling of medications must include comprehensive information such as:

- Name and strength of medicine

- Dosage of strength

- Expiry date

- Warning and Precautions

- Route of administration

Pharmaceutical companies are required to follow strict regulations concerning different aspects of their products, including but not limited to how they are identified, dosage information, expiration dates, storage conditions, and safety warnings.

Pharmaceutical companies face major obstacles when it comes to labelling pharmaceutical products due to the value of what’s inside the container, limited labelling areas, and strict regulatory requirements. The readability and accuracy of information are crucial but can be difficult to achieve given the delicate nature of the pharmaceutical containers. Keeping up with standards is also critical, making the labelling process even more challenging.

Newman’s Labelling machines have different levels of automation, including reject station and verification, barcode, automatic loading/unloading station, and many more.

OUR CLIENTS